Rensselaer Polytechnic Institute Professor Jie Lian Develops New Layering Process for Graphene

November 5, 2015

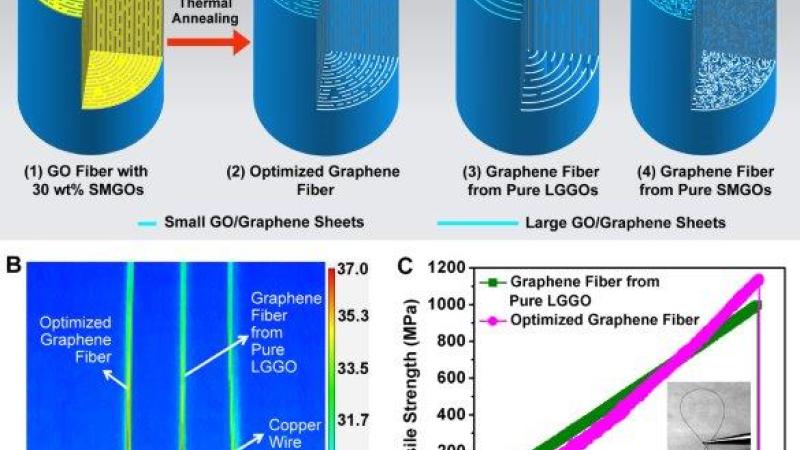

Troy, N.Y. — Graphene, a single layer of carbon atoms bonded in a hexagonal pattern, is simultaneously the thinnest, strongest, and stiffest known material, and also serves as an excellent conductor of both heat and electricity. However, these superior properties have yet to be realized for graphene-derived macroscopic structures such as graphene fibers. In research published in the journal Science, researchers at Rensselaer Polytechnic Institute have developed a new layered structure for graphene that transforms high-quality 2-D graphene sheets into its 3-D form while maintaining its attractive thermal and electrical properties and mechanical strength.

According to Jie Lian, associate professor of nuclear engineering in the Department of Mechanical, Aerospace, and Nuclear Engineering at Rensselaer, the innovations of this breakthrough mainly lie in both technological and scientific aspects.

“Technologically, it is unprecedented to insert large and small-sized graphene nanosheets and assemble them into high-ordered and compact 3-D macroscopic structures,” said Lian. “The fiber achieves very high thermal conductivity, outperforming the best mesophase pitch-based carbon fibers, and is much superior to the state-of-the-art graphene fibers. “Scientifically, a new inner fiber structure differing from conventional carbon fibers was developed responsible for the highly thermally/electrically conductive and mechanically strong graphene fibers.”

The fiber was made with a scalable wet spinning process. The strategy involved using different sized sheet structures which, Lian believes, can be applied to construct macroscopic structures (papers, fibers, tubes, and fabrics) for other materials with 2-D sheet structures or potential 2-D elements.

“The inner structures of the carbon fibers have been studied over decades; however, this study of graphene-based fibers is still in the cradle. This research will inspire tremendous interests and scientific impact on the study of the inner structure for a mechanistic understanding of superior thermal behavior,” Lian said.

Lian’s research program is focused on better understanding advanced materials and nanomaterials to help further nuclear energy production. Looking forward to the design of future generations of nuclear reactors and other nuclear technologies, it will be necessary to develop materials with enhanced performance that are able to sustain exposure to radiation, high temperatures, and corrosion. Such radiation-tolerant materials may be able to extend the lifetime of components, and contribute to the safer, more reliable operation of nuclear systems.

Overall, the study of “nuclear materials” bridges together the fields of advanced materials, nanotechnology, and nuclear engineering.

According to Lian, potential applications of the graphene fibers include thermal management for high-power electronics due to its high thermal conductivity. The highly thermally conductive and mechanical strong fibers can be used as additives or fillers for the fiber-reinforced ceramic/glass/polymer composites to further increase the mechanical strength, and thermal and electrical conductivity of the composites. Further possibilities may be explored for thermal actuators and constructing fabric structures by integrating other functional materials, e.g., thermal energy storage, electrochemical energy storage, and better membranes for filtration and purification. These applications remain to be explored.

To move it forward, Lian plans to continue to work to better understand the fiber structure, particularly on the molecular orientation and macroscopic ordering, and underlying mechanisms governing thermal-mechanical properties. Of particular interest, the superior thermal properties but inferior mechanical properties of the graphene fibers, according to Young’s modulus – which is a number that measures an object or substance’s resistance to being deformed elastically (i.e., non-permanently) when a force is applied to it – are deviated from common knowledge of carbon fibers in which a close correlation between thermal conductivity and Young’s modulus was identified.

The fundamental understanding of the process – microstructure – properties correlation will enable new sciences for the creation of graphene fibers with even more of 2-D graphene’s positive attributes. Lian’s team is also interested in scalable production of large quantities of macroscopic graphene fibers, e.g., by additive manufacturing, to fully unlock the potentials of more conductive and stronger graphene fibers for a wider range of technological applications.

Along with Lian, coauthors of the paper are: Rensselaer MANE graduate students Guoqing Xin, Tiankai Yao, and Spencer Michael Scot; and recent graduate Hongtao Sun; former Department of Electrical, Computer, and Systems Engineering research associate Dali Shao; and former visiting student Gongkai Wang. The research is supported by the National Science Foundation.

This groundbreaking work illustrates how Rensselaer embodies “The New Polytechnic,” a new paradigm for teaching, learning, and research. Using advanced technologies, and enabling cross-discipline collaboration, The New Polytechnic is making a difference in the global impact of research, innovative pedagogy, and in the lives of Rensselaer students.

To read the research paper published in Science, visit: http://www.sciencemag.org/content/349/6252/1083