New device for making masks reusable in fight against COVID-19 being tested at Mount Sinai

April 23, 2020

TROY, N.Y. — The shortage of critical personal protective equipment (PPE) has been a persistent problem for medical and other front-line workers as they battle the COVID-19 pandemic at close range day after day. A team of researchers at Rensselaer Polytechnic Institute has developed a potential solution: a machine that uses ultraviolet (UVC) light to sterilize thousands of protective masks each day, rendering them safe for reuse.

“At Rensselaer, we are focused on solving global challenges, and the COVID-19 pandemic is certainly among the most significant of these in our lifetimes,” said Rensselaer President Shirley Ann Jackson. “Our interdisciplinary approach, combined with the passion and ingenuity of our researchers, enables us to contribute solutions in this crisis that will continue to be helpful even after it has passed.”

This project began at the request of longtime research partners at Mount Sinai. As the pandemic worsened in New York City, and the shortage of PPE deepened, they asked if Rensselaer could develop a way to make critical resources last longer without losing their effectiveness.

The speed with which the Rensselaer team devised and built this solution expedites the possibility that it will be helpful in the fight against the pandemic. A design and construction process that often takes months, or even years, was completed in a matter of weeks.

“These are anxious moments for all of us as we look at what’s going on in the country and also across the world, and we all want to do something to make a difference,” said Deepak Vashishth, the director of the Center for Biotechnology and Interdisciplinary Studies (CBIS) at Rensselaer.

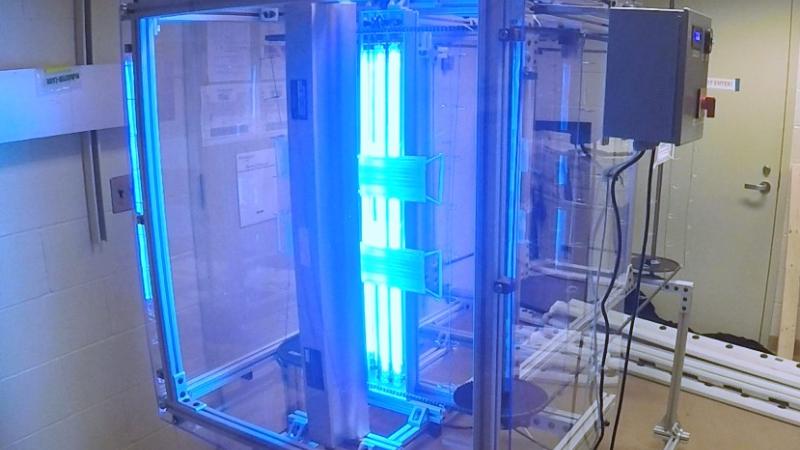

The UVC sterilization system, developed by a multidisciplinary team of engineers from across Rensselaer, stands about eight feet tall and about eight feet long. Two UVC lamp fixtures, each containing two UVC tubes, are attached vertically across from one another so that masks — hung on a series of hooks that are part of a motorized belt system — can pass in between the two UVC sources. The speed of that belt determines the dose of radiation that the masks receive.

According to Bob Karlicek, the director of the Center for Lighting Enabled Systems & Applications (LESA) at Rensselaer, the system is unique because of its vertical setup, which allows light to disinfect the masks from both sides.

“Since UVC radiation is a line-of-sight disinfection process, if there’s any shadow from the mask or any material blocking the access of UVC radiation to the mask, you’re not going to disinfect that part,” Karlicek said. “We elected to come up with a system that allowed us to run the masks vertically so we could simultaneously expose the masks from both the front and the back without blocking any UVC radiation.”

Karlicek designed and built the machine with Mohammed Alnaggar, an assistant professor of civil and environmental engineering, and Arunas Tuzikas, a senior staff engineer within LESA. They worked with Mattheos Koffas, a professor of chemical and biological engineering, as well as senior research staff within CBIS — including Brigitte Arduini, Jason Davis, and Sergey Pryshchep — and doctoral students Deepika Vaidyanathan and Sneha Gopal. As members of the lab run by Jonathan Dordick, a professor of chemical and biological engineering, Vaidyanathan and Gopal worked remotely to analyze data as it was gathered, accelerating the team’s efforts to calibrate the system to the proper UVC dose.

“If the dose is too high, the UVC radiation can damage the elastic straps, causing them to break after a number of disinfection cycles. We also didn’t want the dose to be too low, because then we wouldn’t be able to disinfect the mask,” Karlicek said.

The efficacy of this system will be tested at Mount Sinai on masks that have been infected with the virus that causes COVID-19. That information will help Rensselaer engineers adjust the speed of the belt for better results. From there, this system still needs to be approved for use by the Food and Drug Administration.

“Normally these things take a very long period of time, but given the national situation, I think there is an understanding at all levels that we need to look for solutions which are stable, good, and safe, and are delivered quickly,” Vashishth said. “I think this is an example of where we came together to deliver a solution, and hopefully, this is going to be useful to the health-care professionals and front-line workers.”