New method produces ultra-thin membranes with record-breaking sensitivity, promising to transform thermal imaging and night vision technology

August 18, 2025

Rensselaer Polytechnic Institute (RPI) scientists played a pivotal role in the development of a new manufacturing technique that could revolutionize infrared detection technology, making thermal imaging devices smaller, more accurate and far more affordable.

The research, published recently in Nature, introduces an innovative "atomic lift-off" method that creates ultra-thin crystalline membranes capable of detecting infrared radiation with high sensitivity, and without the need for expensive and bulky cooling systems.

Prior efforts to mass-produce the fragile membranes had been stymied by the difficulty of keeping them intact while removing them from their manufacturing substrates. The team, which in addition to RPI included researchers from MIT and several other universities, were able to surmount that problem and achieve high-precision exfoliation of the membranes.

"This method offers an approach to manufacturing cooling-free detectors that can cover the full far-infrared spectrum, marking a notable advancement in detector technology,” the researchers write.

Ultra-thin layers of semiconducting crystal material are typically “grown” atop a substrate with a similar crystal structure. But removing the ultra-thin films from the substrates has proven to be a formidable challenge. The films often bond too tightly to the substrates, making them virtually impossible to remove without damaging their delicate structure.

One approach has been to insert a sacrificial release layer as a buffer between the film and the substrate to facilitate its removal, acting like the Teflon layer of a non-stick pan. But those efforts add a great deal of complexity and cost to the process.

Yunfeng Shi, Ph.D., a professor in RPI’s School of Engineering and one of the lead authors on the paper, demonstrated with his colleagues that the process can be done without a buffer layer if the material used to make the ultra-thin film contains lead. Shi’s group carried out density functional theory calculations showing that lead atoms reduce charge transfer across the film-substrate interface, weaking interfacial bonds and facilitating atomic lift-off.

“We demonstrate that the release layer used in conventional exfoliation is in fact not necessary for certain systems,” Shi said. “This is paradigm changing.”

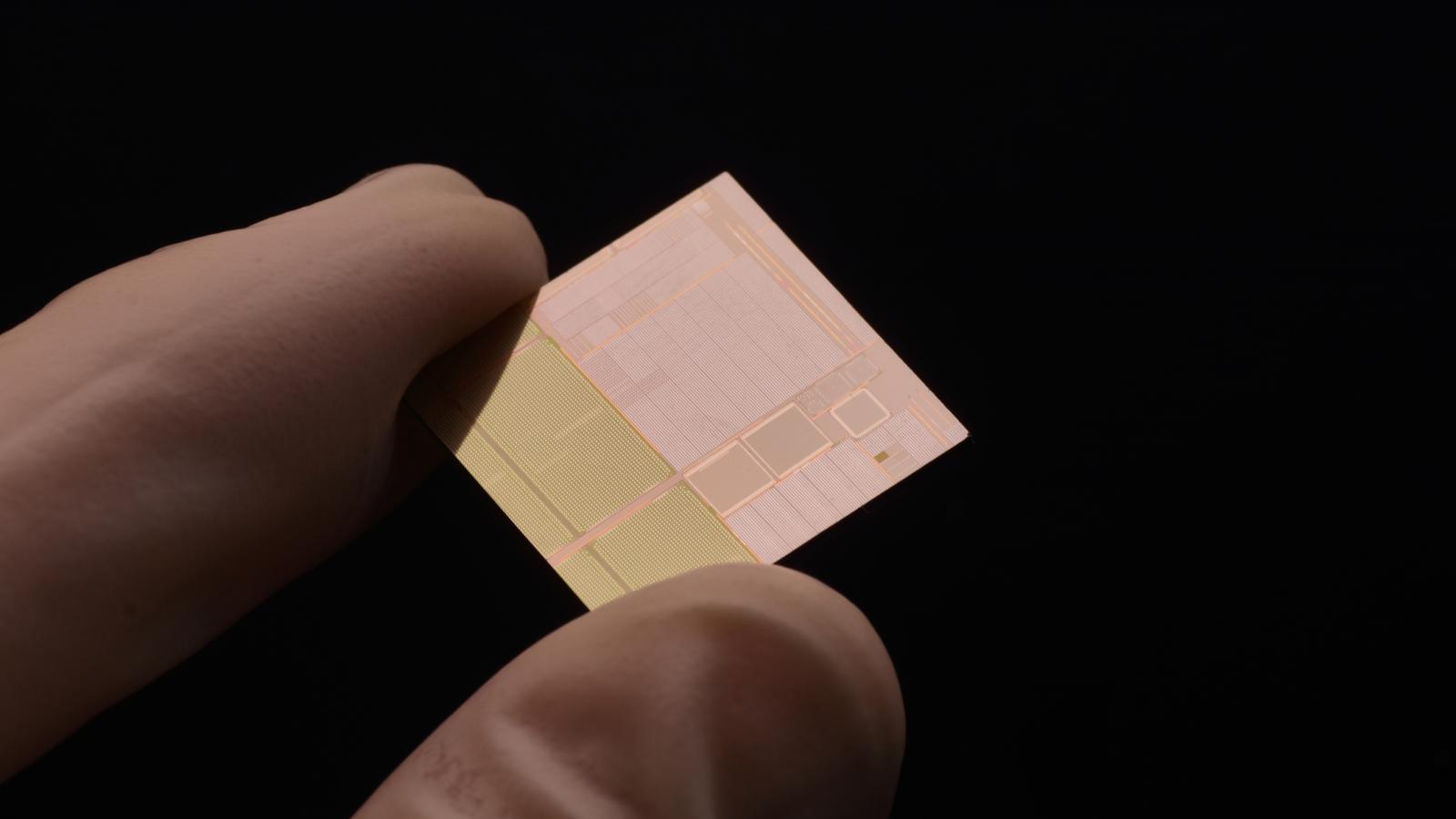

Using this technique, the researchers were able to bulk-produce thin films of a substance called PMN-PT, a pyroelectric material that generates electric currents in response to heat. They were able to achieve record levels of thermal sensitivity, made possible because they were able to shrink the membranes down to a thickness of just 10 nanometers.

In addition to night vision technology, the improvement in thermal sensitivity could lead to advances in biomedical and astronomical imaging technology, or in realms like autonomous driving, where it could be used to improve collision detection in low-light situations. The researchers also say the technique could be used to improve many different types of crystalline oxide membranes, not just infrared-detecting ones.

“This breakthrough underscores the transformative power of combining advanced materials synthesis and manufacturing with state-of-the-art computation,” said Shekhar Garde, Ph.D., Thomas R. Farino Jr. ’67 and Patricia E. Farino Dean of the School of Engineering. “Uniting experimental ingenuity with high-fidelity modeling through interdisciplinary collaborations, Yunfeng Shi and colleagues have demonstrated what has eluded experts for years. I look forward to the many practical applications that will come from this advance.”

The work was supported by grants from the Air Force Office of Scientific Research, the U.S. Department of Energy, and other sources.

The full study is available at the following link: Atomic lift-off of epitaxial membranes for cooling-free infrared detection