October 10, 2019

Advanced robotics manufacturing has the potential to vastly improve, speed up, and create safer manufacturing processes to design and create the things we interact with each day, while saving money. It combines cutting-edge robotics, artificial intelligence, and emerging technologies.

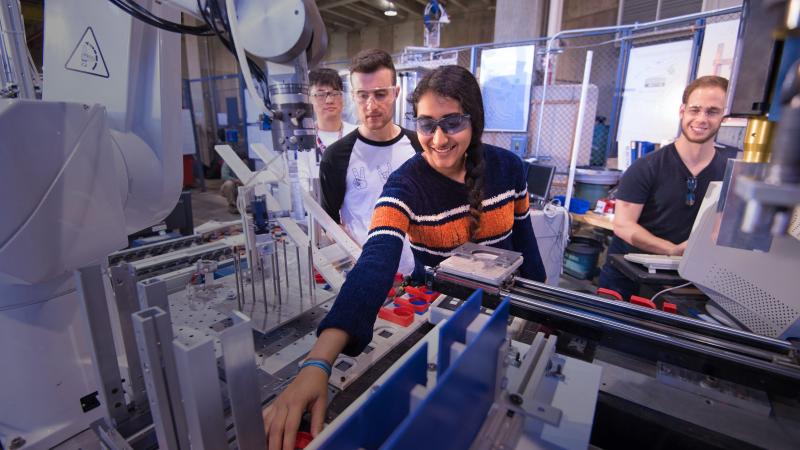

Rensselaer Polytechnic Institute is leading a number of projects aimed at improving next-generation manufacturing. For example, several projects focus on various aspects of composites manufacturing; one research team is working to develop a cost-effective robotic sewing system; and another is creating an interoperable middleware that will allow different robots to easily work with sensors and software designed by multiple venders and over multiple platforms.

Those efforts are among eight recent projects Rensselaer has had a hand in with the support of Advanced Robotics for Manufacturing (ARM), four of them led by researchers at Rensselaer. The grants for these projects combined total more than $2 million in funding from ARM and more than $4 million in cost sharing from Rensselaer and partner organizations.

One of 14 Manufacturing USA® Institutes throughout the United States, ARM is a national membership-based consortium that is dedicated to advancing the state of robotics and supporting workforce education to support the nation’s manufacturing base growth and global impact. It is a public-private partnership that brings academia, industry and technologists together to develop real-world solutions to be used on manufacturing floors.

“ARM provides a wonderful opportunity for Rensselaer students, staff, and faculty to work with industry to learn about current practice, challenges, and needs in advanced manufacturing. These ARM-funded projects, together with New York state matching grant support and Rensselaer’s own investment, have enabled this exciting industry-government-academia collaboration to develop solutions and tools for manufacturing innovation,” said John Wen, head of the department of electrical, computer, and systems engineering, and leader of Rensselaer and New York state’s participation in ARM.

Rensselaer is committed to developing the technologies that will enable the future of automation and robotics, made further evident by its Center for Automation Technologies and Systems (CATS) — which has long been an innovation partner for industry — and the Manufacturing Innovation Learning Laboratory (MILL) — which gives students the skills to imagine and create the next manufacturing advances.

In a similar vein, one of the newest grants will support the creation of a pre-apprentice training and certification project. It’s an effort to strengthen the STEM pipeline by developing a scalable teacher training and certification process at the junior and senior high school level and ARM certification process for students.